Title: The C-Series 2 Engine: Redefining Heavy-Duty Diesel Performance

Introduction

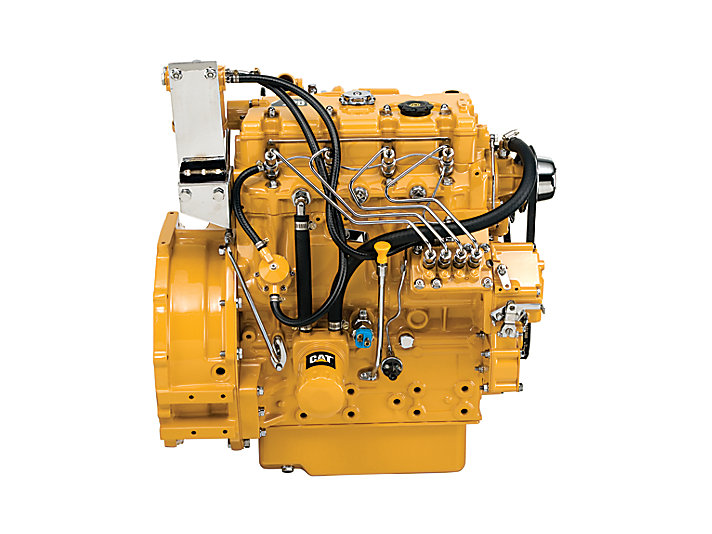

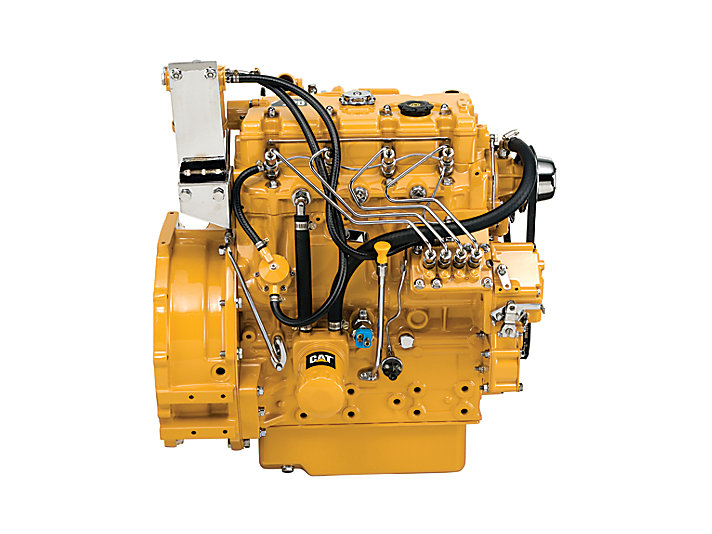

Modern heavy-duty diesel technology has taken a significant leap forward with the introduction of the C-Series 2 engine. Designed for versatility across construction, mining, and power-generation sectors, this power unit combines high output with cleaner operation and compact packaging. The following overview examines its core attributes, practical advantages, and growing influence on industrial markets worldwide.

Engine Design and Features

The C-Series 2 is a six-cylinder, in-line, turbocharged, charge-air-cooled diesel. Its architecture balances generous torque reserves with frugal fuel use and reduced exhaust pollutants, while a space-saving envelope allows installation in equipment where room is limited.

Central to the engine is an advanced combustion strategy that optimizes fuel burn, cutting smoke and nitrogen-oxide formation without sacrificing power. This clean-combustion approach also stretches each litre of diesel further, lowering overall carbon footprint.

A further highlight is the fully electronic control module. By interpreting data from multiple sensors every second, the module fine-tunes injection timing, boost pressure, and after-treatment dosing so the engine delivers consistent performance whether idling on a cold morning or working at full load under tropical sun.

Performance and Reliability

Output spans roughly 160 to 210 horsepower, giving the unit enough muscle for demanding cycles such as trenching, rock loading, or prime power supply. Sturdy internals, reinforced bearing shells, and a stiff cylinder block shrug off shock loads, dust, and temperature swings common on remote sites.

Field experience indicates high endurance, with many examples logging thousands of hours before the first top-end service. Such longevity stems from conservative engineering margins, premium materials, and exhaustive validation tests that simulate extreme thermal and mechanical stress.

Applications and Market Impact

Contractors fit the C-Series 2 to hydraulic excavators, wheel loaders, and backhoe loaders, where its generous low-speed torque speeds cycle times and reduces fuel bills. Cleaner exhaust chemistry also helps fleets meet increasingly strict emissions guidelines on urban projects.

Mine operators rely on the same engine to propel haul trucks, loaders, and dozers that move overburden 24 hours a day. High reliability and long oil-change intervals keep machines available, while efficient combustion trims diesel spend—an important saving when fuel is flown or trucked to remote pits.

In power generation, the unit drives portable and stationary gensets that electrify camps, hospitals, and process plants far from the grid. Stable frequency, rapid load acceptance, and low noise make it a practical choice for both standby and continuous duty.

Competitive Analysis

Several manufacturers offer rival diesels in the same class, yet the C-Series 2 differentiates itself through integrated electronics, robust after-treatment, and a global support network. These factors have helped the engine secure a growing share of the mid-range heavy-duty segment, even as overall market growth remains moderate.

Conclusion

By combining strong performance, compact size, and cleaner exhaust, the C-Series 2 has carved out a distinct position in the industrial diesel arena. Its adaptability across construction, mining, and energy projects underlines a design philosophy that prizes both productivity and environmental responsibility. As industries continue to seek lower operating costs and tighter emissions compliance, engines of this calibre are set to remain central to heavy equipment fleets around the world.

Ultimately, the C-Series 2 exemplifies how modern engineering can deliver power without compromise—offering owners dependable service, reduced fuel expenditure, and the flexibility to tackle diverse tasks in challenging conditions.